Metal swarf, fumes and whirring things with sharp edges are all largely incompatible with tiny infants. As is spare money. And spare time. And sleep. However, an inveterate tinkerer needs to tinker, and I’ve been beguiled by the siren-song of miniature aviation…

Happily, it turns out that toddlers can be entertained by flying models. Now, flying models do tend to have whirring things with sharp edges, but that’s why the good Lord gave us quick reflexes and the ability to shout “nooooo!” in such a way as to cause temporary paralysis in three-year-olds. And also kill switches on our transmitters.

It further transpires that model ’planes are surprisingly hard to fly properly. Trickier than real ones, I think. The little ’un now thinks that “crash” is a synonym for “land” (also “bugger”, “argh!”, etc.) – something we’re going to need to clear up before taking him on any more commercial flights.

Back in the day, if you wanted to fly model aeroplanes, the deal was you spent every evening all winter gluing and pinning balsa wood and inhaling a range of allergens and cellulose thinners, and then the first dry day of spring, after faffing about with nitromethane, risking eardrums and fingertips to get your little engine going, you watched your masterpiece experience some serious accelerated entropy as you failed to take account of ground-effect wind-shear on finals or were imprudent with the centre of gravity or something. Then you blamed the expensive but shonky radio gear and started accumulating Plans and balsa for the next season.

This sort of thing is incompatible with toddlers unless you have a very traditional “other half” who is happy to be left holding, changing, feeding, clothing and generally dealing with the baby full-time. Or a team of nannies, if you’re posh.

These days, though, we have superb radio gear that costs next to nothing and is far too effective and reliable plausibly to be blamed for destroying models (though people still try…) and we have Foamies (model planes made of the kind of stuff that was originally intended to protect other stuff from severe impacts,) and we have RTF (“Ready To Fly”) and we have ARTF (“Almost Ready To Fly”) and we have fuss-free and very effective electric power options. Basically, you can now substitute a bit of cash for an entire winter spent inhaling dangerous substances and getting divorced. And, with Foamies, you can get the hang of flying models a lot quicker, because Foamies are often good for multiple attempts at landing.

So, one of my recent-ish acquisitions is a surprisingly cheap one metre wingspan model Pitts Special biplane, made of some kind of foam. Among the many economies embraced in the design of this “VNRTF” model is a propeller attachment that is, frankly, rubbish. The thing’s powered by a 12v-ish lithium-ion battery driving an electric motor, which has ample power and very surprising duration (over ten minutes from a mere 1300mAh). The motor has a long 4mm diameter shaft with an M4 thread along all but about 2mm of its length. The manufacturer has optimistically furnished it with a pair of ordinary-sized M4 nuts and a small washer by way of a seating for the propeller. The prop is 10 inches in diameter, and it clears the ground by approximately 3/5 of bugger-all, especially when the ’plane’s taxiing up on its main wheels with the tail in the air. So when the prop blades strike a small tussock of grass or moss or a conveniently placed half-brick, the prop is wrenched around and the nuts dig in to the prop hub and it then runs massively out of true with a tremendous vibration and much loss of power. No amount of messing about with spanners and rulers will get it to run true thereafter, there’s simply not enough seat area on the side of an M4 nut, or even a normal M4 washer, to keep a propeller hub decently aligned.

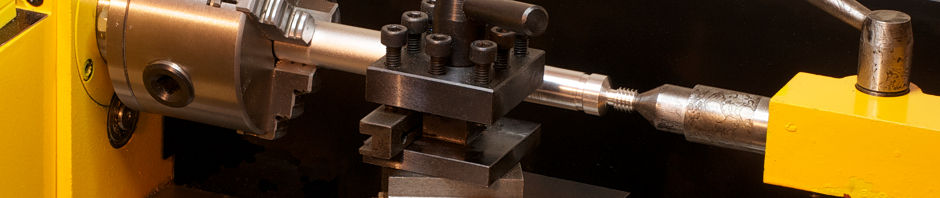

So I lifted the dust cover on the lathe, and peered beneath. It’s still there. Watch this space…

Like your lathe gear calculator program. not being able to myself can it be altered to be used with a 12tpi leadscrew ,which is fitted to my lathe a Warco 180v

Hi Geoffrey,

It can indeed be modified, pretty easily in fact – I’ll try to add a few more leadscrew options; if I fail to get around to it, take a copy of the page and look at line 920, it ought to be pretty obvious what you need to insert to get another leadscrew option, just make a copy of line 920, paste it between line 920 and 921 and change ’16’ to ’12’ in the new line. Oh and get rid of the “selected” bit in one or other of them – that marks the default line on loading.

Update: Done it now – there are some more leadscrew options to choose from, including 12tpi. I guess I should add a freeform entry where you fill in the tpi yourself, but that’s probably not such a quick fix…