It started like this:

I have a friend, Austin, who Makes Things. Tricycles, principally. He has an extensive workshop featuring, among other stuff, a lathe. I have another friend, Ben, who’s into video and film-making, and he’s always after bits and bobs of “grip equipment” to facilitate such follies as shooting video on a digital stills camera. For non-film-people, “grip equipment” is stuff generally used for supporting or moving things when making films – tripods, microphone and lamp stands, dollies, stuff like that.

I also have a big mouth…

“Oh, ” I caught myself saying to Ben, as he complained bitterly about the disappointingly short and unhelpfully un-threaded microphone stalk he’d eventually received from a US supplier, after around a month and a few anguished e-mails. “I could design a much better mic stalk to fit your rig than that.” Ben was skeptical. “Could you actually make one, though?”

“Well, my mate Austin could make one in his workshop in no time.”

I live in Bristol, as does Ben. Austin’s workshop is in mid-Wales, miles away…

While over at Austin’s supervising his construction of the mother of all microphone stalks, I remembered that my half brother, Dave, who also lives in mid-Wales, bought himself a small second-hand hobby lathe some time back which, as far as I know, he’s never used. Mostly because he has nowhere to set it up right now.

I don’t really have anywhere to set it up either, but I do have a couple of yet-to-be-decorated rooms in my newly purchased house, and a greater willingness to improvise, so I called him and asked if I could perhaps borrow it. “No problem, come around and fetch it”, he said.

Smaller than I remembered, it lurked in a corner, tucked out of the way under a blanket. “Hangon,” said Dave from the other room, as I tried to work out why this little thing was glued to the floor (it weighs 40kg), “I have some more bits here, stashed away in the airing cupboard. Erm. Oh shit.”

Hot water tanks don’t generally leak without you knowing about it, but it turns out that their overflow pipes can leak quite a bit and go completely un-noticed, so long as there’s a waterproof plastic bucket full of lathe parts directly underneath.

Picking the various bits out of a porridge of decomposing cardboard boxes steeped in rusty water was a depressing affair, and tedious, but I eventually got them all superficially hosed down and stashed in a plastic bag.

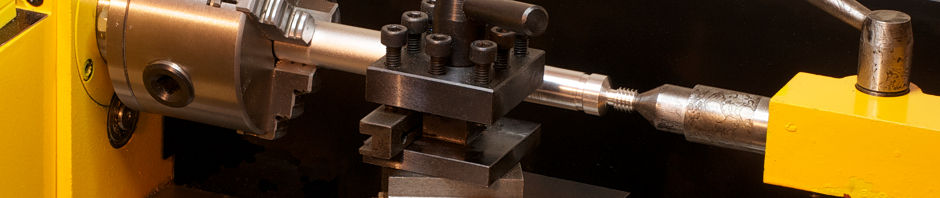

The lathe itself was in near-immaculate condition, but among the ancilliaries that had been soaking for who-knows how long were vital things like the tailstock, so my first job on getting it all home was a couple of hours with a bucket, a scrubbing brush, some very fine wet-or-dry sandpaper and lots of elbow grease. And actual grease.

The damage was remarkably slight. I wrote off the original toolkit – spanners and allen keys are easier to replace than to de-rust – and everything else is servicable. The travelling steady and fixed steady looked like they’d never been unpacked from new, and their packing grease worked well, they’re in far better condition than I had any right to expect – the paint’s suffered a bit and the nuts had rusted, but otherwise pretty good. The tailstock quill is discoloured and mildly pitted at the end. All fixing nuts were rusted, but they’re just standard metric sizes so I replaced most of them with stainless ones I had to hand. The chuck key and tailstock locking nut lost their nice blue/black finish, the outside chuck jaws might be a bit of a dodgy fit now – I lightly polished the rust off them and the tool holder using 600grit wet-or-dry, used wet and kept flat on a bit of glass. By and large, though, everything vital and tricky to replace seems servicable.

The damage was remarkably slight. I wrote off the original toolkit – spanners and allen keys are easier to replace than to de-rust – and everything else is servicable. The travelling steady and fixed steady looked like they’d never been unpacked from new, and their packing grease worked well, they’re in far better condition than I had any right to expect – the paint’s suffered a bit and the nuts had rusted, but otherwise pretty good. The tailstock quill is discoloured and mildly pitted at the end. All fixing nuts were rusted, but they’re just standard metric sizes so I replaced most of them with stainless ones I had to hand. The chuck key and tailstock locking nut lost their nice blue/black finish, the outside chuck jaws might be a bit of a dodgy fit now – I lightly polished the rust off them and the tool holder using 600grit wet-or-dry, used wet and kept flat on a bit of glass. By and large, though, everything vital and tricky to replace seems servicable.

I retired from my first day of lathe ownership moderately satisfied. Home-made grip equipment seemed a little closer…

Oh yeah, the mic stalk which Austin made to my design went down a storm. “This is perfect,” said Ben, clearly delighted. He’ll have thought of something else he desperately needs long before I’m up to speed with my little borrowed lathe, though.

glad the mike thing worked… you’ll be after a 127 tooth gear yet 🙂

Heh, I might be, but it’ll probably have to go in its own seperate little gearbox and/or be a different pitch to the standard ones – those “1 module” gears are the diameter in mm of their number of teeth, so 127T would be 63.5mm radius, and there’s only about 80mm between the leadscrew and drive idler, and not enough room below the leadscrew I don’t think. On the other hand, by my calculations a 63T gear would give ratios a lot closer to a lot of the metric pitches – close enough to be practical in the majority of ’em. Or I could just get the metric leadscrew 🙂 (Or, more adventurously, modify the lathe to have two leadscrews at once, so I can do metric & imperial and generally use the other one for power feed when set up on one for thread cutting… hmm…